Gateway Bookbinding Systems Ltd. has been manufacturing plastic spiral binding for over 60 years. Those years have yielded a tremendous amount of experience in the areas of plastic extrusion and the forming coil.

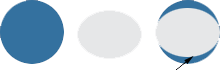

PLASTIKOIL® filament - For years, Gateway Bookbinding has endorsed the many advantages of working with an elliptical profile of plastic filament. For those customers manufacturing coil in-house, this elliptical PLASTIKOIL® filament - versus a round profile - results in much higher yields per pound of formed coil. The elliptical profile has also been proven to work better with automated coil insertion equipment. Gateway maintains a large inventory of spooled filament, with our extrusion department operating 24 hours a day so that we can provide our customers with quick and efficient turnaround.

The Advantages Of PLASTIKOIL® Filament

- Made from top quality, high grade PVC

- 45 different colors to choose from

- Custom color matches / custom filament diameters also available

- Disposable spools (No spool deposits or spools to return)

- Manageable 25 lb. (11 kg) spools maintained in inventory

- RecyKoil filament available - manufactured from recycled materials that are sourced outside of Gateway's own internal production

- PETG filament also available as an alternative to PVC

- In-Stock - Large inventories of Black / White / Clear maintained at all times

- Fast turnaround - 24 hour production

| Standard PLASTIKOIL® Filament Profiles |

PLASTIKOIL® Lite Filament Profiles |

Corresponding Coil Diameters |

| 1.8 mm (.072") | 1.6 mm (.063") | 6 - 9 mm |

| 2.0 mm (.080") | 1.8 mm (.072") | 10 - 13 mm |

| 2.2 mm (.088") | 2.0 mm (.080") | 14 - 17 mm |

| 2.4 mm (.096") | 2.2 mm (.088") | 18 - 23 mm |

| 2.6 mm (.104") | 2.4 mm (.096") | 25 - 32 mm |

| 2.8 mm (.110") | 35 - 42 mm | |

| 3.0 mm (.118") | 45 - 50 mm |